Julia Greer

A Tiny Solution for a Titan of a Problem

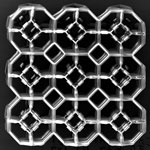

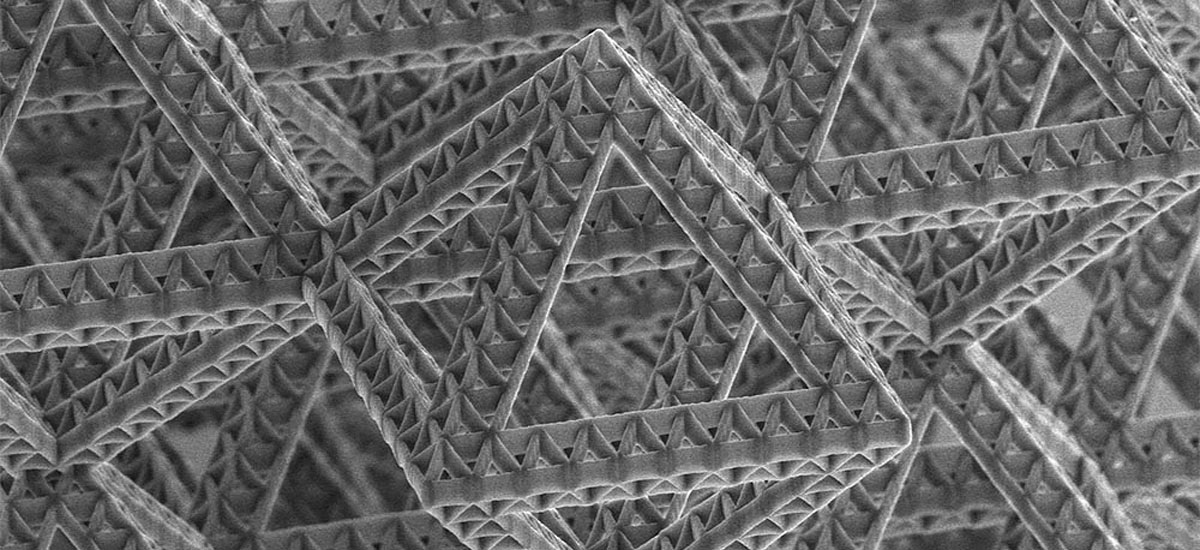

Julia Greer, Caltech Professor of Materials Science, Mechanics, and Medical Engineering, creates and studies new ultra-light and strong materials by combining 3-dimensional architectures with the natural strength of nanoscale materials. “We look at different properties that are offered by each type of a conventional material at different length scales, and then we combine them together into these intricate architectures to get entirely new classes of materials,” she explains. Using a laser to selectively harden a polymer along a given path, her group sculpts delicate lattices that serve as scaffolds to hold up materials with desirable properties. “It can be a ceramic, it can be a semiconductor, it can be a metal or an oxide. And then we etch away the polymer, and so what we’re left with is this hollow nano-lattice.” Built almost entirely of air, the resulting material is extremely lightweight and exceptionally strong. “At these length scales, materials become significantly stronger, or they can become non-breakable and they can exhibit very beneficial properties. And then when you wrap this nano-ribbon around a three-dimensional architecture, you create a new material.”

Using novel 3D patterning fabrication and a combination of experiments, finite element analysis, and theory, Greer's group is developing new principles that describe the mechanics of lattice architectures because classical theories are insufficient to capture the full range of their mechanical properties. Greer is bridging the gap between in-situ mechanical experiments and computationally efficient models, with the objective of developing scaling laws that can better predict the mechanical behavior of the nano-architected materials that are currently being manufactured.

Greer's research focus also lies in synthesizing functional resins which can be used in two-photon lithography and 3D printing to fabricate cross-linked architectures with a variety of chemical functionalities, which range from surface functional ligands (i. e. thiols, N-BOC, octane, aromatics, DNA, pharmaceutical compounds, etc.) to shape-memory polymers, whose shape can be programmed at a particular temperature and then mechanically altered, to DNA origami that can be used for large-area nano-patterning.

Greer’s drive to innovate landed her an invitation in 2010 to lead a KISS workshop focused on getting to Titan, an icy moon of Saturn. “The KISS study was the first time that I really thought about the possibility of applying our nanomaterials research toward space-related problems.” At the extremely low temperatures — around 95 Kelvin — that any Titan lander would have to withstand, most materials become stiffer and more prone to fracture. “That moon is teeming with incredible organic chemistry, but how are you going to probe it if everything is going to break because it becomes brittle? So it was truly a material problem, in addition to the chemistry, and the measurement, and the instrument, and all of the other plethora of problems that were there.”

“

The KISS study was the first time that I really thought about the possibility of applying our nanomaterials research toward space-related problems.

”

The KISS study got Greer thinking about how to create new materials that can retain their strength even in Titan’s deep freeze. “How can we utilize the architecture and the size effect of nanomaterials in such a way that we can suppress the ductile-to-brittle transition and, for example, make materials that won’t shatter at these temperatures?” To approach that problem, she had to break down old assumptions, combining the best properties of different materials at multiple scales. “This is sort of my mantra in research in general: We’re all about breaking the rules. We’re all about not subscribing to what had been known for centuries. We’re all about enabling other possibilities.”

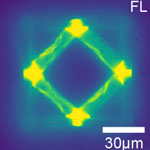

Greer's team is focused on designing, fabricating, and testing nano-architected all-solid-state Li-ion battery cells that consist of nano-architected, mechanically resilient anodes made of variety of different materials. Beyond developing novel electrode geometries for better battery cell performance, Greer's research addresses fundamental questions about mechanisms of ion transport through solid electrolytes, reaction mechanisms, and electrochemistry of architected anodes/cathodes.

We’re All About Breaking the Rules

The study’s collaborative environment allowed Greer the opportunity to brainstorm with colleagues across a wide array of fields, each approaching a Titan mission with a unique perspective. “KISS is all about thinking outside the box, and I think that’s very much facilitated by bringing in people with different expertise.” As study co-lead, she facilitated discussions between chemists, geologists, planetary scientists, and JPL engineers. “What was really neat about that study is it was such a diverse group of people,” she recalls. “The incredible experience of meeting with these people and diversifying my own network of colleagues, and also diversifying our knowledge and seeing these applications, made me really appreciate what kinds of problems that materials can help solve.”

“

KISS is all about thinking outside the box, and I think that’s very much facilitated by bringing in people with different expertise.

”

A Sense of Discovery

Creative sessions at the workshop bloomed into a new research direction for Greer, who followed up on that initiative to venture into the cold. “We actually weren’t really thinking about cryogenic applications so much before at all. What KISS inspired me to do is to really start thinking about these nano-lattices as a possible material for functioning at these cold temperatures.” What started out as a topic of discussion soon became a tangible goal in the lab. “In many ways, it’s all thanks to KISS that we now understand these cryogenic properties in addition to the nanometer size effect properties of the different materials.” Follow-on funding from the KISS Titan study allowed the Greer group to extend their experiments to extremely low temperatures. “KISS funding enabled us to add the cryogenic testing capability to our in situ nanomechanical instruments that we already had, and we wouldn’t have been able to do it otherwise.”

“

KISS funding enabled us to add the cryogenic testing capability to our in situ nanomechanical instruments that we already had, and we wouldn’t have been able to do it otherwise.

”

Julia Greer

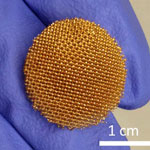

Looking ahead, the Greer group is focused on scaling up their production capabilities for these ultra-light and super-strong materials. “Scaling them up would really enable their insertion into quite a few technological applications, including the space ones.” As the potential for her new materials grows, so does Greer’s enthusiasm. “I absolutely love doing this because there’s this sense of discovery. We have no idea what to expect, there are no models, and so it’s just really exciting to be able to see how far we can push this material kingdom.”