Technical Development - Completed 2012

Coherent Arrays for Astronomy and Remote Sensing

Final ReportMarch 2011 Progress Update

Tony Readhead (California Institute of Technology)

Campus PI

Charles Lawrence (Jet Propulsion Laboratory)

JPL PI

Overview

Improve Device Noise Performance

Our goal is to reduce the equivalent noise temperature achievable with cryogenically-cooled InP HEMT transistors by a factor of 2-3 from current limits, to less than three times the quantum noise. Based on measurements of existing 35nm gate MMICs at room temperature above 160 GHz, this should be achievable within the next two years in the frequency range 30 to 120 or 150 GHz, and up to 300GHz on a longer timescale.

Integrate MMICs into arrays without loss of performance

The overall goal of the work is to achieve near-quantum-limited performance in the basic building blocks of massive arrays of coherent detectors for radiometry, polarimetry, interferometry, and high resolution spectroscopy in the frequency ranges 70–280 GHz. The key now is to realize the full performance potential of the transistors and MMICs (as developed in Goal #1) in a unit cell package that enables massive arrays.

This requires cryogenic measurement and characterization of MMICs and other components, isolation of the critical factors in performance, design and fabrication iterations, and exquisite control of fabrication.

Specific goals are to produce modules (both direct detection for continuum work and heterodyne for spectroscopy and interferometry) with the following noise performance:

- < 3q, 70–118GHz (current state of the art is 6q)

- < 5q, 120–160GHz (current state of the art is 10q)

- < 10q, 180–280GHz (current state of the art is 20q)

High Performance, Low Mass, Inexpensive Feed Arrays

The goal here is to reduce mass and cost while maintaining a very high level of performance, assesed by sidelobe levels, losses, and bandpass characteristics. This work will focus initially on smooth-walled alternatives to corrugated feeds that promise excellent performance with greatly improved manufacturability.

Array Interconnects

If cryogenic investigation determines that commercial metallization is not suitable, lower thermal conductivity metal (e.g., phosphor bronze) will be evaporated on commercial substrate for cryogenic applications.

Commercial connectors exist for ribbon interconnects for DC applications. For RF applications, we will investigate custom RF connector designs in microstrip, coplanar waveguide, or stripline, first through full-wave EM and mechanical analysis, then with test fixtures to measure performance via vector network analyzer measurements, and finally measuring cryogenic performance and reliability in a test cryostat fixture.

Mass-Production Techniques

Fabrication of precision micromachined waveguide structures is a vital component for almost all MMIC circuits. Sophisticated CNC machining techniques have been little used in micromachining of waveguide blocks because small numbers in the past have not justified the effort necessary to implement and refine mass production techniques. Future focal plane arrays with many hundreds of modules will benefit greatly from these techniques.

High performance micromachining systems at Arizona State University and the University of Arizona already offer large work volumes, high-speed CNC controllers and high capacity toolchangers. Automated touch probes and tool measurement systems are in place. These machines can complete all machining operations on a waveguide block (both waveguide features and other low precision machining) in a single run.

The capability exists for palletization for the manufacture of dozens of blocks in one machine setup, at frequencies above 300 GHz. With the addition of pallet changers and automated part feed, production rates of dozens per day could be achieved. We will develop machining techniques to produce waveguide modules using these palletization techniques, and will be able to simultaneously supply other efforts within the KISS program with necessary waveguide blocks at a low cost.

March 2011 Progress Update

The major tasks on this project over the last year have been:

- Outfitting a new laboratory for radio frequency and digital work

- Measurements and testing of Monolithic Microwave Integrated Circuits (MMICs)

- Testing and Development of Receiver Modules

New Laboratory

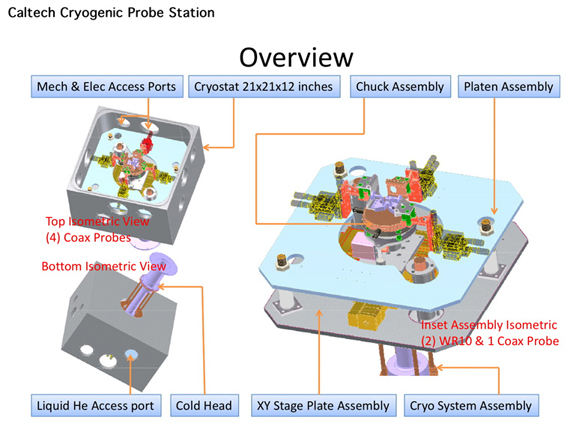

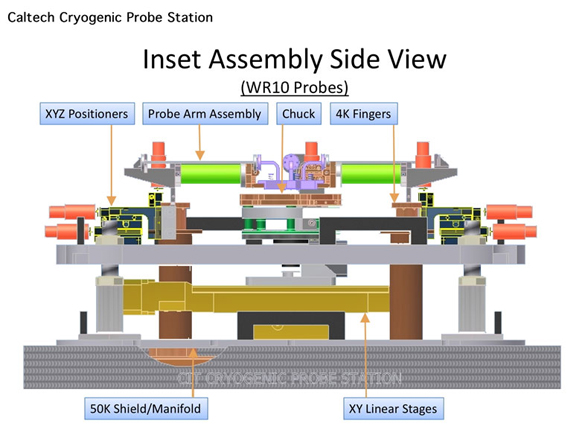

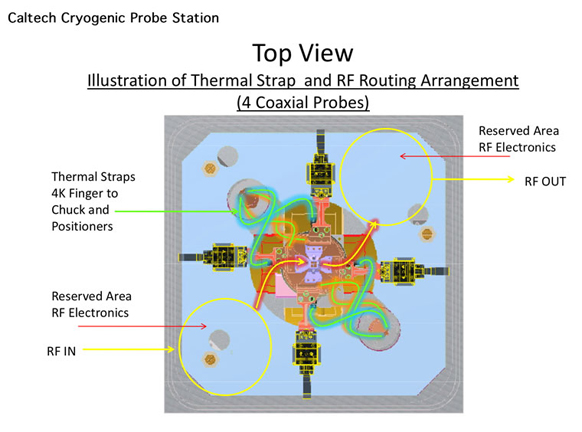

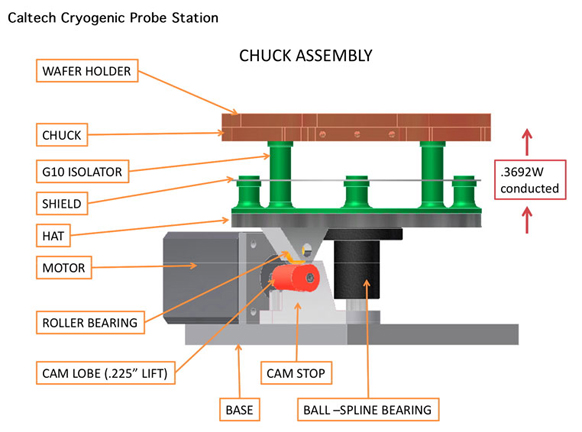

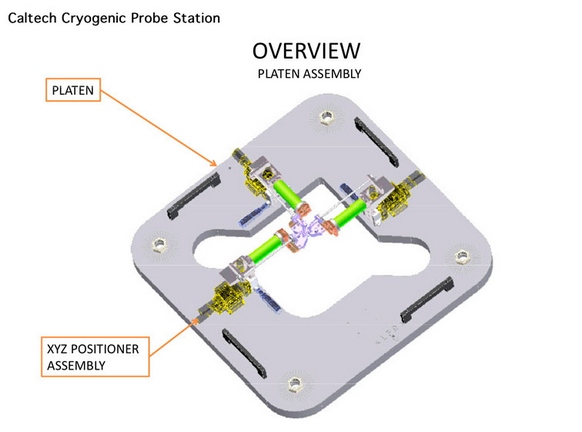

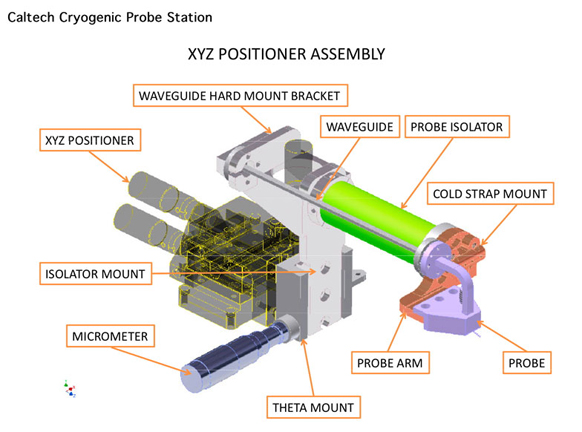

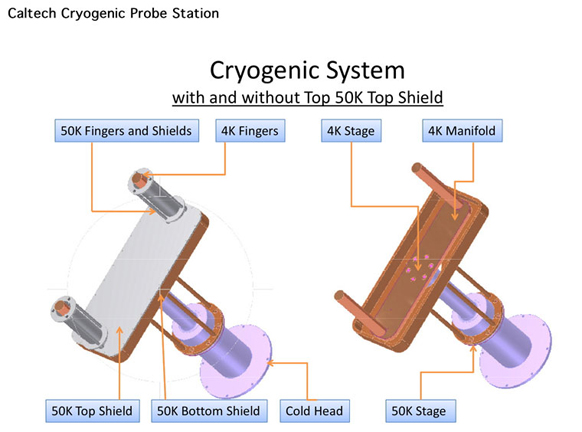

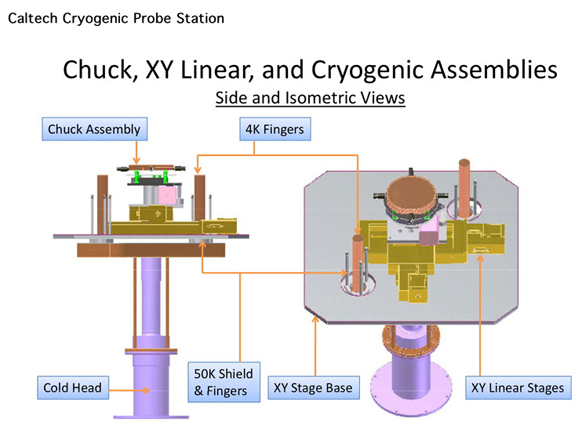

We have completely outfitted a new laboratory – the Cahill Radio Astronomy Laboratory (CRAL) for radio frequency work and for digital work and we have designed and built a cryo-probe test station (CPTS) for testing undiced MMIC wafers up to four inches in size. This fabrication has just been completed and we are now carrying out our first cryo-tests of the equipment. Within a few weeks we expect to be making measurements of the wafers themselves. In the words of John Carlstrom – this is a real “game changer”.

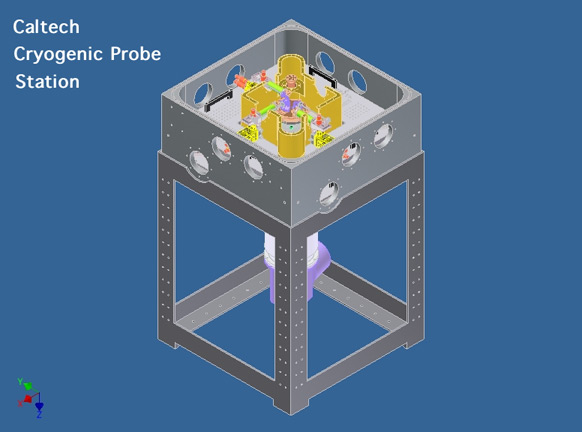

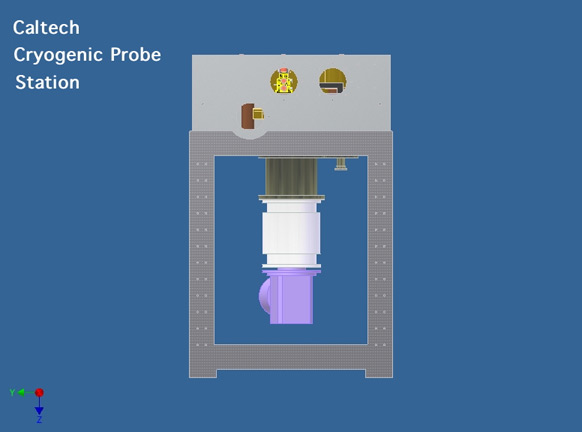

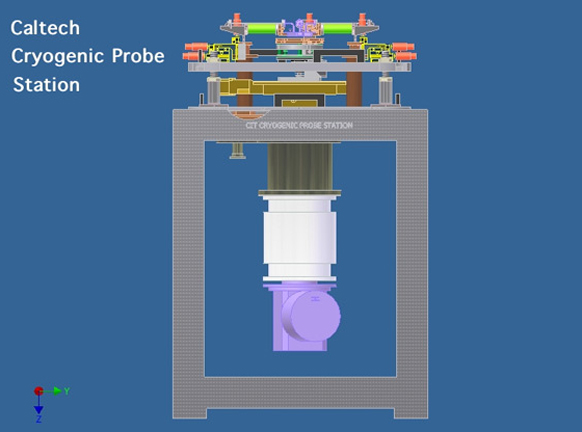

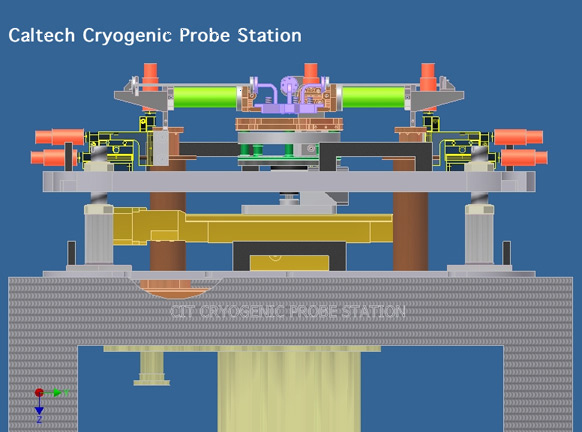

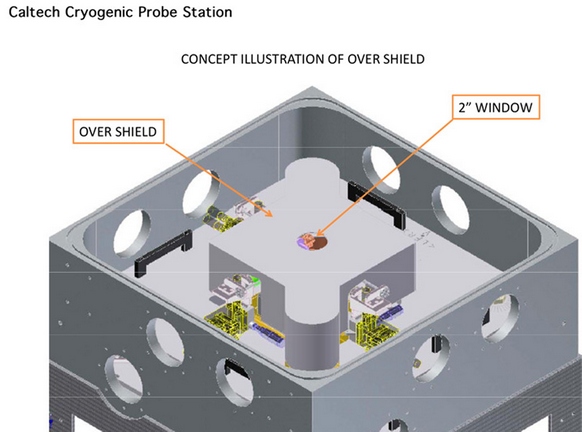

Figure 1. Caltech Cryoprobe Station

Program of MMICs Measurement and Testing

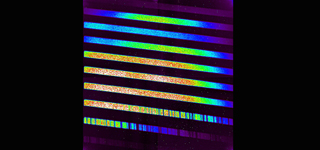

We have just recently begun our program of measurement and testing of Monolithic Microwave Integrated Circuits (MMICs). An excellent example is shown in below.

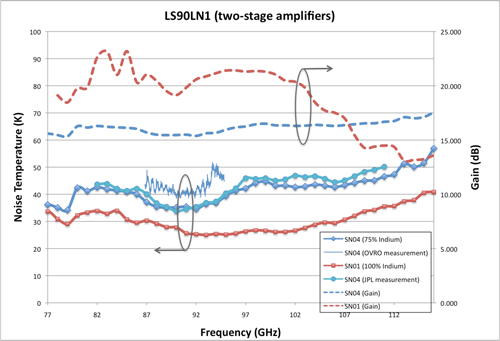

Figure 2. MMIC testing results for two MMICs – SN01 and SN04

This shows results for two MMICs – SN01 and SN04. SN04 has been tested at JPL and in the CRAL – the two blue plots show the excellent agreement between the JPL and CRAL measurements. This device has also been tested in the lab at the Owens Valley Radio Observatory (OVRO) – see the short blue curve. The OVRO results are 5K-10K higher than the JPL and CRAL results. We are investigating this discrepancy. The results shown for SN01 (red curves) are extremely encouraging with a noise temperature below 41 K from 77 GH to 116 GHz. In terms of bandwidth plus noise temperature, this is the best device that has been produced, but its gain is rather low for our needs. The hope on the present program is to produce devices with noise temperatures about a factor two below what we see here and with gain greater than 20 dB.

MMIC Module Understanding

We have been making rapid progress in understanding our MMIC modules. We have broken some QUIET 90 GHz modules up into three sections – i.e. we have split up the module – in such a way that we can, for the first time, test the radio frequency performance of the MMICs inside the module packaging. A major breakthrough a few weeks ago was the discovery that our MMICs, when placed in modules, are oscillating at 67 GHz. It is clear that a considerable signal at this frequency was travelling back to the orthomode transducer and then being reflected back into the MMIC, thereby raising the noise temperature of the module, which was running at around 100K, i.e. about 50K higher than the individual MMICs. We are now working on redesign of the module packaging to eliminate the oscillation at 67 GHz.